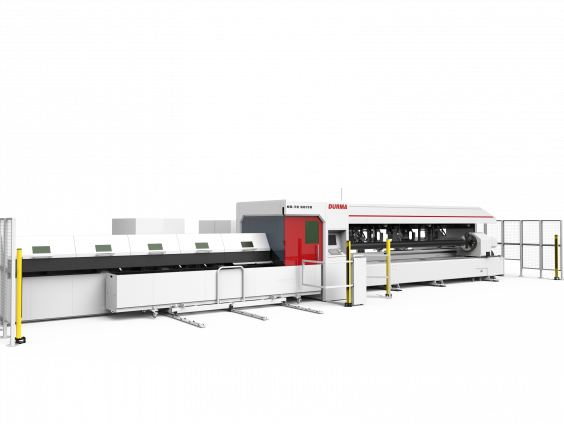

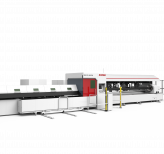

Torulaser HD-TC Durma

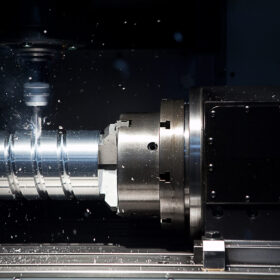

Torude laserlõikus on välja töötatud spetsiaalselt ettevõtetele, mis hindavad torude (läbimõõduga kuni 220 mm) ja profiilide kvaliteetset lõikamist. Tänu torulaseri kuni 3 kW lõikevõimsusele on võimalik lõigata torusid ja profiilmaterjale paksusega 0,8 mm kuni 10 mm. Täisautomaatne sisestamine ja väljastamine nõuab vähem vaeva ja säästab operaatori aega. Liikuvaid telgi juhivad hooldusvabad, dünaamilised ja suure jõudlusega AC-servomootorid. Laserlõikusel tekkiv tolm imetakse imisüsteemi abil tolmukogumisfiltrisse.

Automaatne torude ja profiilide sisestussüsteem on konstrueeritud materjali ettevalmistamise ajakulu vähendamiseks ning automaatne torude ja profiilide väljastussüsteem kogub lõigatud materjali kokku masina tööd peatamata. Tänu torulaseri kompaktsele ehitusele vajavad kõik torude ja profiilide sisestamise / lõikamise / väljastamise töömomendid vähem ruumi ja vähem töötlemist. Torude laserlõikuspink HD-TC eristub oma kiiruse, kvaliteetsete komponentide, tõhususe ja tööstusdisaini poolest.

Torude laserlõikuspinki HD-TC saab kasutada paljudes tööstusvaldkondades nt autode, mööbli, riiulisüsteemide ja masinate tootmine, ehitus, põllutöömasinad ja teraskonstruktsioonid. Torude ja profiilide kasutamine on paljudes valdkondades laialt levinud. Protsessid, nt geomeetriliste kujundite lõikamine, toimivad lihtsalt. Lasertehnoloogia kasutamine torude ja profiilide lõikamisel annab võimaluse esteetiliste ja paindlike disainide loomiseks.

Mis on Durma torulaseri HD-TC eelised?

- Kasutajasõbralik

Durma torulaser HD-TC on spetsiaalselt välja töötatud kasutajasõbralikkust silmas pidades. Selle automatiseeritud tööprotsess säästab teie aega. Ergonoomiline ehitus muudab selle hõlpsasti kasutatavaks. - Energiatõhus

Durma torude laserlõikuspink HD-TC on välja töötatud energiatõhusust silmas pidades. Selle kõrgtasemel tehnoloogia ja disain on ruumi ja energia säästmiseks võimalikult optimaalsed. Masin on kiire, ergonoomiline ja hõlbus kasutada. Kõrgtasemel tehnoloogia hoiab masina käituskulud madalal. - Usaldusväärne

Durma tehnoloogia on valmistatud täpsete tulemuste tagamiseks. Durma torulaser HD-TC on vastupidav ja töökindel ning teenib teid pikki aastaid. Täpne tehnoloogia tagab usaldusväärse tulemuse.

Saadaval on kaks erinevat seadet:

Durma HD-TC 60170 (max diameeter 170mm, nelikant max 120mm, ristkülik 150*100mm)

Durma HD-TC 60220 (max diameeter 220mm, nelikant 160mm, ristkülik 200*100mm)

Madalad käidukulud

Madal energiakulu

Madal kulu komponendi kohta

Optimeeritud fookuskaugus kõigi paksuste korral

Hooldusvaba talitlus

Kompaktne kujundus, kiire paigaldus

Jäik kerekonstruktsioon, suur vastupidavus

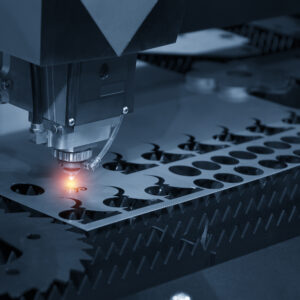

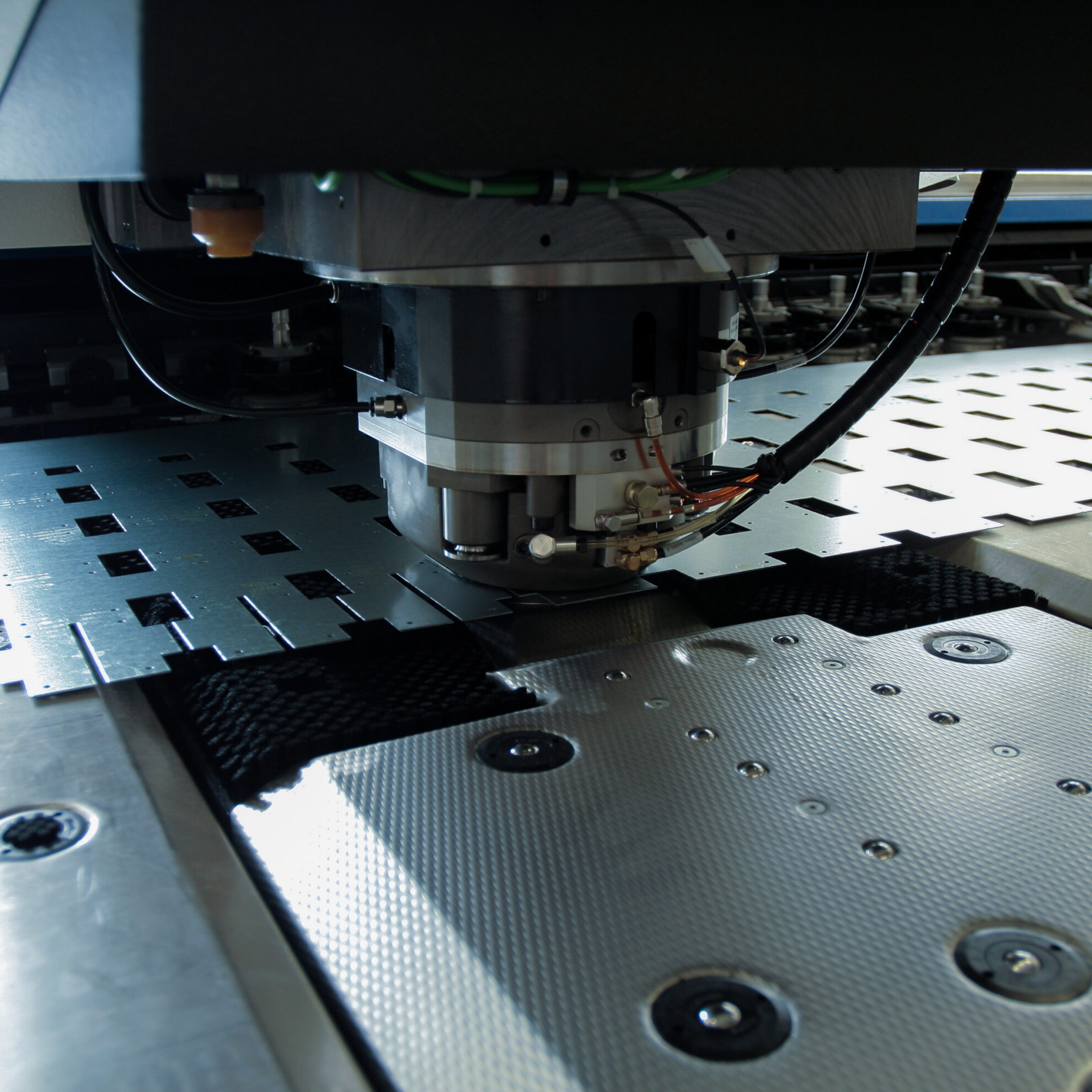

Laserlõikepea

ProCutter pakub tervikliku lahenduse õhukeste ja keskmise paksusega materjalide laserpõhiseks sulatuslõikamiseks. Leeklõikamise korral saab töödelda ka paksemaid materjale, hoides sealjuures alal kõrgeid kvaliteedistandardeid.

Automaatne laadimissüsteem

Profiilid viiakse virnast üksteise järel teisaldusketile, süsteem liigutab profiili üles, haaratsid võtavad profiilist kinni ja liigutavad selle padruni teljele, padrun hoiab profiili.

Profiili pikkuse mõõtmine

Servomootori abil toimub profiili pikkuse mõõtmine ja andmete edastamine süsteemi.

Torude teisaldussüsteem

Torude teisaldussüsteem tagab torude suunamise lõikeliinile õiges asendis.

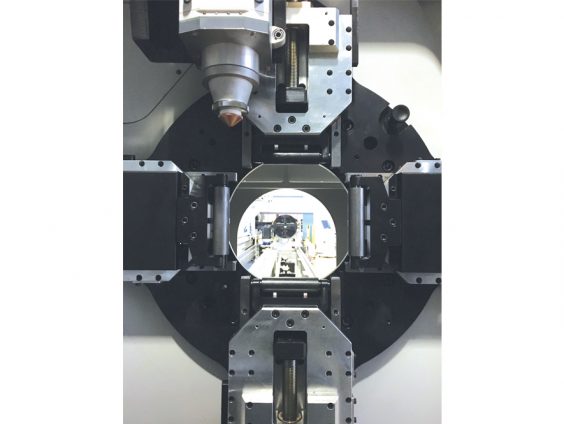

Hüdrauliline profiilihoidik

Võimaldab hoida mitmesuguseid profiile 4 klambri abil, mis toimivad sõltumatult 2+2 põhimõttel. Hüdrorõhk on automaatselt reguleeritav vastavalt profiilimaterjali paksusele.

Kett-teisaldussüsteem

Kett-teisaldussüsteem võimaldab laadida roostevabast terasest, alumiiniumist, messingist jms. torusid neid kriimustamata.

Z-telg

Võimaldab kiiremat lõikeprotsessi tänu kõrgele dünaamilisele sooritusvõimele. Autofookusega laseripea vähendab lõikamisele kuluvat ajakadu eelnevas ettevalmistusfaasis.

Automaatse laadimise haardesüsteem

Laadimisüksuselt saabuvad torud teisaldatakse lõikealale ja tsentreeritakse automaatselt.

Profiilide tugisüsteem

4 tugihaara servomootoritega hoiavad laadimist samal tasandil hüdraulilise padruniga. Kui hüdrauliline padrun liigutab profiili mööda X1-telge, sulguvad tugihaarad üksteise järel hüdraulilise padruni esiosa avamiseks.

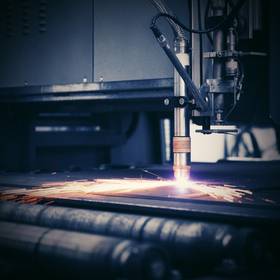

Pritsmekaitsesüsteem

Pritsmekaitsesüsteemi kasutatakse lõikeserval moodustuva räbu profiili vastaspinna külge kinnijäämise ärahoidmiseks. Profiili sisepinnaga nakkuvad kraadid langetavad lõikekvaliteeti ja tekitavad vajaduse detailide sisepinna puhastamise järele. Pritsmekaitsesüsteem hoiab kõik need probleemid ära.

Automaatne väljastussüsteem

Väljastusüksuse tugimehhanismi kõrgust ohjab servomootor, profiili toetatakse lõikamise ajal.

Saadaval on 4 m ja 6 m variandid.

Saadaval on variandid esi- ja tagaküljele.

Väljastuslaud saab eemaldada lõigatud torud kabiinist oma sisse-välja liikumisega.

Õmbluse tuvastusandur

HDTC masinatele paigaldatud õmbluse tuvastusandur tuvastab õmblusega pinna toru

laadimisel masinasse ja võimaldab pöörata operaatori lõigatud avad suvalise nurga alla.

Tsentreerimissüsteem laseranduritega

HDTC masinatele hiljuti lisatud laseranduritega tsentreerimise võimaluse abil saab kontrollida profiili suurust ja ebaühtlast struktuuri lõikamise ajal või enne lõikamist andurite abil selle tagamiseks, et lõigatavad sisekontuurid on korralikult tsentreeritud.

| Torulõikuse tehnilised andmed | HD-TC 60170 | HD-TC 60220 |

| Maks. läbimõõt (mm) | Ø170 | Ø220 |

| Maks. nelikanttoru suurus (mm) | 120×120 | 160×160 |

| Maks. ristküliktoru suurus (mm) | 150×100 | 200×100 |

| Min. läbimõõt (mm) | Ø20 (Ø12 manuaalselt) | Ø20 (Ø12 manuaalselt) |

| Maks. toru pikkus (mm) | 6500 | 6500 |

| Min. toru pikkus (automaatsel laadimisel) | 3000 | 3000 |

| Maks. toru kaal (kg/m) | 37,5 | 52 |

| Maks. materjali paksus (mm) (2 kW korral) | 8 | |

| Min. materjali paksus (mm) | 0,8 | |

| Automaatne laadimine | Jah | Jah |

| Automaatne väljastus | Jah | Jah |

| Lõikepea | 2D | |

| Padrunite arv | 1 | |

| Tsentreerimispadrun | Jah | Jah |

| Viimati lõigatud toru pikkus (mm) | 185 | |

| Kaasaveopadruni kiirus (m/min) | 90 | |

| Kaasaveopadruni kiirendus (m/s2) | 10 | |

| Täpsus (mm) | ±0,20 | |

| Positsioonimistäpsus (mm) | ±0,05 | |

| Torude tüübid | Ümar, nelikant, ristkülik, ellips H, C, U, L |