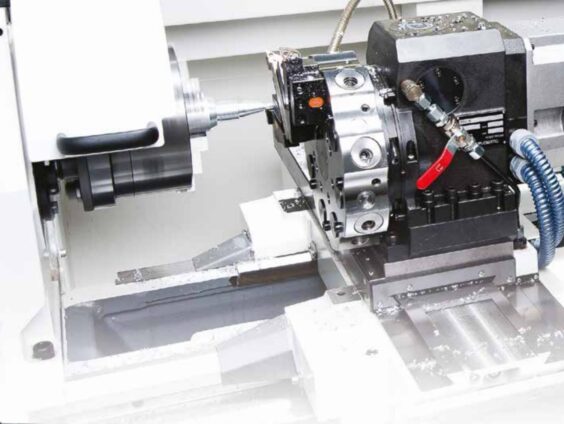

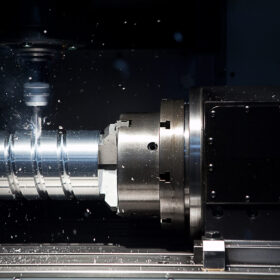

CNC tsentertreipink MASTURN 550i/820i

Lihtsad masinad, mis sobivad tükitoodete valmistamiseks ja väikeste partiide tootmiseks.

Kõrge täpsus, tootlikkus, kasutajasõbralikkus.

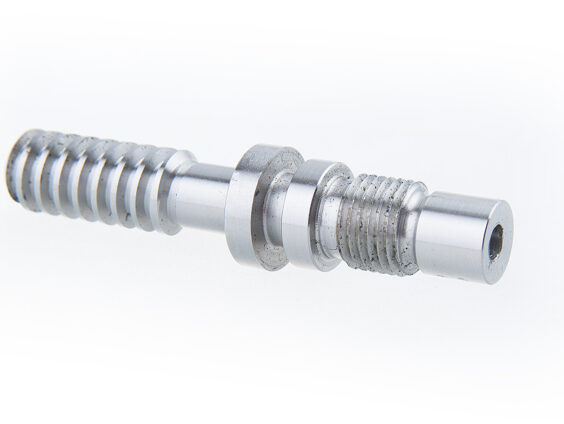

Ühtlane lõikekiirus – kõrge kvaliteediga komponentide masintöötlus.

Masintöötluse graafiline simulatsioon.

Käsitsi masintöötluse võimalus nagu traditsioonilistel treipinkidel või automaatsete fikseeritud tsüklitega arvjuhtimissüsteemi toel.

Programmi saab kirjutada kontuurprogrammi või DIN-programmina.

Lõiketingimused ja töödeldava komponendi kuju geomeetrilised andmed, kus neid automaatselt töödeldakse, sisestatakse klaviatuuril juhtsüsteemi.

Soovi korral saab programmide loomise ja nende rakendamise tarkvara arvutisse.

| Standardvarustus | MT 550i 800 / 1 500

MT 820i 2000 / 3000 / 4500 |

MT 550i Live Tool 1500

MT 820i Live Tool 2000 / 3000 |

| Tööruumi valgustus | ✔️ | ✔️ |

| Fikseeritud tsenter | ✔️ | ✔️ |

| Spindli adapter | ✔️ | ✔️ |

| Kaasaveoketas | ✔️ | ✔️ |

| Tööruumi ümbris | ✔️ | ✔️ |

| Tööriistajahutus | ✔️ | ✔️ |

| Hooldustööriistade komplekt | ✔️ | ✔️ |

| Kasutusjuhend | ✔️ | ✔️ |

| HEIDENHAIN MANUAL plus 620; SIEMENS 828 Manual Turn | ✔️ | ✔️ |

| ERIVARUSTUS | ||

| Kolme pakiga padrun | ✔️ | ✔️ |

| Nelja pakiga padrun | ✔️ | ✔️ |

| Plaanseib | ✔️ | ✔️ |

| Liikumatu lünett | ✔️ | ✔️ |

| Liigutatav lünett | ✔️ | ❌ |

| Liigutatav lünett revolverpea jaoks | ✔️ | ❌ |

| Latijuhik | ✔️ | ✔️ |

| Torusuunajad | ✔️ | ✔️ |

| Materjalitõkis spindlis | ✔️ | ✔️ |

| Liigutatav tsenter Röhm | ✔️ | ✔️ |

| Laastukonveier | ✔️ | ✔️ |

| Laastumahuti | ✔️ | ✔️ |

| Tõsteseadmestik | ✔️ | ✔️ |

| Kiirhoidik MULTIFIX | ✔️ | ❌ |

| 8-positsiooniline revolverpea | ✔️ | ❌ |

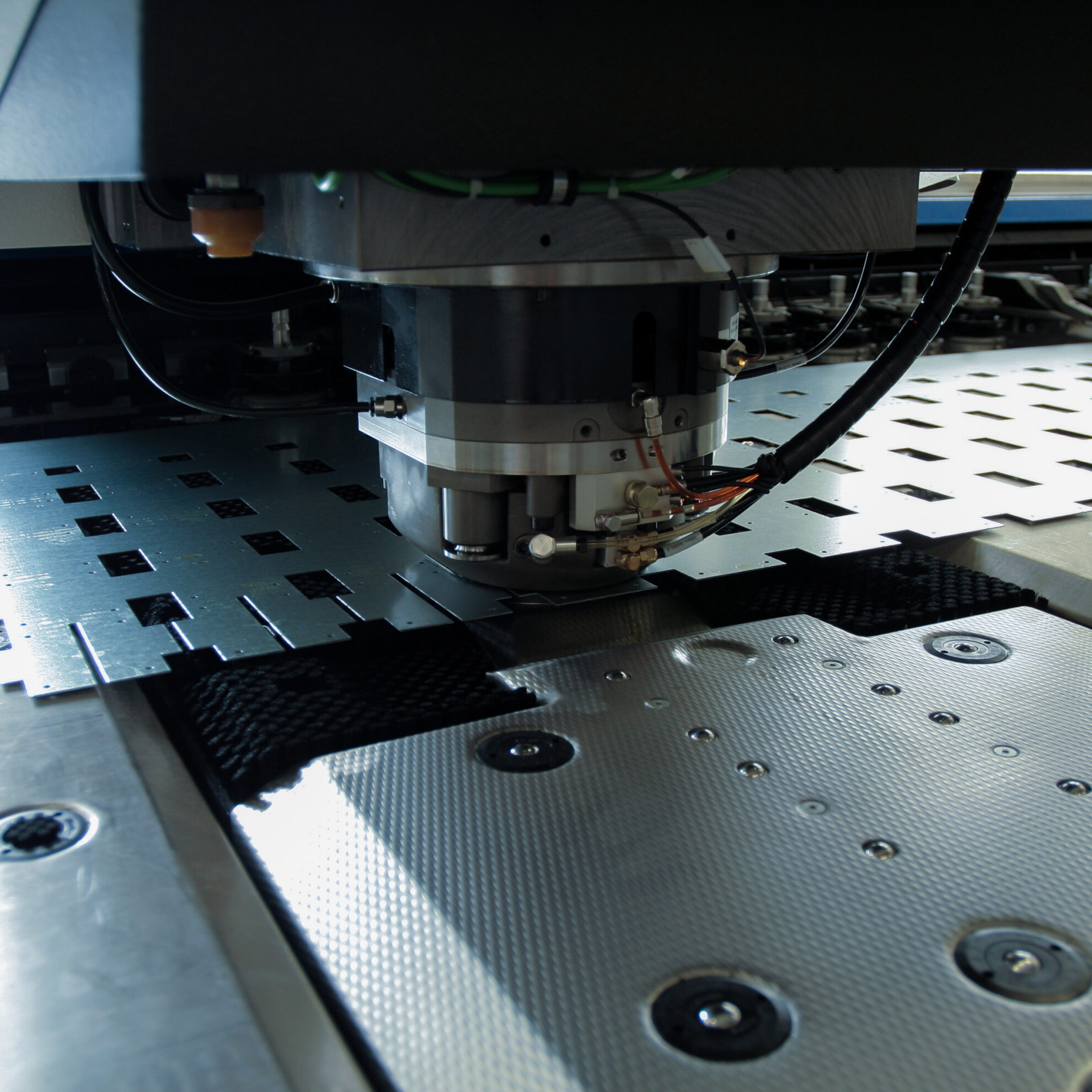

| 8-positsiooniline revolverpea – käitatavad tööriistad | ❌ | ✔️ |

| Tehnoloogiline tarkvara Data Pilot 620 | ✔️ | ✔️ |

| Tehnoloogiline tarkvara kontuuride importimiseks DXF vormingus (ainult Heidenhaini korral) | ✔️ | ✔️ |

| Lülituskilbi jahutus – õhukonditsioneer | ✔️ | ✔️ |

| Varuosade kataloog | ✔️ | ✔️ |

| Tehnilised andmed | MASTURN 550i 800 / 1 500 | MASTURN 550i 800 / 1 500 LiveTool | MASTURN 820i 2 000 / 3 000 / 4 500 | MASTURN 820i 2 000 / 3 000 LiveTool | ||

| Töövahemik | Geomeetriline ja töötlustäpsus | mm | ISO 13041-1 | ISO 13041-1 | ISO 13041-1 | ISO 13041-1 |

| Töötlusläbimõõt sängi kohal | mm | 550 | 550 | 820 | 820 | |

| Töötlusläbimõõt ristsupordi kohal | mm | 350 | 350 | 530 | 530 | |

| Tsentrite vahemaa | mm | 900/1600 | 900/1600 | 2 000 / 3 000 / 4 500 | 2 000 / 3 000 | |

| Maks. treitöötluse läbimõõt | mm | 500 | 332 | 720 | 340 | |

| Tooriku kaal – ühepoolne kinnitus | kg | 400 | 400 | 1000 | 1000 | |

| Tooriku kaal – tagapukk + 1 lünett | kg | 1000 | 1000 | 3000 | 3000 | |

| Tööspindel | Spindli esiots (DIN 55027) | ― | 8 | 8 | 11 | 11 |

| Spindli õõs | mm | 82 | 82 | 128 | 128 | |

| Spindli koonus | ― | 90 | 90 | 132 | 132 | |

| Põhiajam | Mootori võimsus | kW | 17 | 17 | 22 | 22 |

| Automaatne kaheastmeline käigukast | mm | 2 astet | 2 astet | 2 astet | 2 astet | |

| Spindli töökiiruste vahemik | min-1 | 0 – 3 000 | 0 – 3 000 | 0 – 1 800 | 0 – 1 800 | |

| 1st käik | min-1 | 0 – 600 | 0 – 600 | 0 – 400 | 0 – 400 | |

| 2st käik | min-1 | 20 – 3 000 | 20 – 3 000 | 20 – 1 800 | 20 – 1 800 | |

| Maks. spindli väändemoment: | ||||||

| 1st käik | Nm | 1300 | 1300 | 1850 | 1850 | |

| 2st käik | Nm | 295 | 295 | 370 | 370 | |

| Telg X | Kuulkruvi – läbimõõt / samm | mm | 25 / 5 | 25 / 5 | 32 / 5 | 32 / 5 |

| Käik | mm | 285 | 267 | 370 | 370 | |

| Kiiretteanne | m. min-1 | 10 | 10 | 10 | 10 | |

| Telg Z | Kuulkruvi – läbimõõt / samm | mm | 40 / 5 | 40 / 5 | 50 / 10 | 50 / 10 |

| Käik | mm | 890 / 1590 | 1517 | 2000/3000/4500 | 1928/2928 | |

| Kiiretteanne | m. min-1 | 10 | 10 | 10; 7,5; 10 | 10; 7,5 | |

| Tööriistapea | mm | * MULTIFIX C positsiooniline revolverpea | * 8-positsiooniline revolverpea – Live Tool | * MULTIFIX D1 8-positsiooniline revolverpea | * 8-p revolverpea

T |

|

| Maks. tööriista profiil | mm | 20 × 20 / 32 × 32 | 20 × 20 | 25 × 25 / 40 × 40 | 25 × 25 | |

| Tagapukk | Pinooli läbimõõt | mm | 90 | 90 | 115 | 115 |

| Pinooli käik | mm | 160 | 160 | 225 | 225 | |

| Pinooli koonus – MORSE | ― | 5 | 5 | 6 | 6 | |

| Toiteühendused ja energiatarve | Masina maks. summaarne sisend | kWA | 30 | 30 | 45 | 45 |

| Masina mõõdud | P x L x K | mm | 2 538 / 3 238 × 1 920 × 1 755 | 2538 / 3 238 × 1 920 × 1 755 | 4 000 / 5 000 / 6 000 × 2 055 × 1 863 | 4 000 / 5 000 × 2 055 × 1 863 |

| Masina kaal | mm | 3 200 / 3 400 | 3200 / 3400 | 4 900 / 5 300 / 6 500 | 4 900 / 5 300 | |

| Juhtsüsteem | mm | HEIDENHAIN MANUAL plus 620 SIEMENS SINUMERIK 828D | HEIDENHAIN MANUAL plus 620 SIEMENS SINUMERIK 828D | HEIDENHAIN MANUAL plus 620 SIEMENS SINUMERIK 828D | HEIDENHAIN MANUAL plus 620 SIEMENS SINUMERIK 828D | |