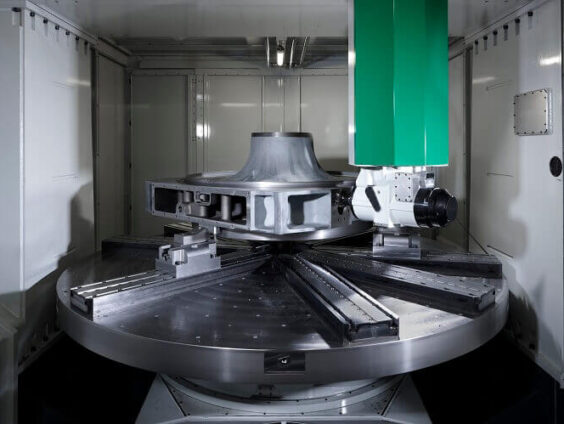

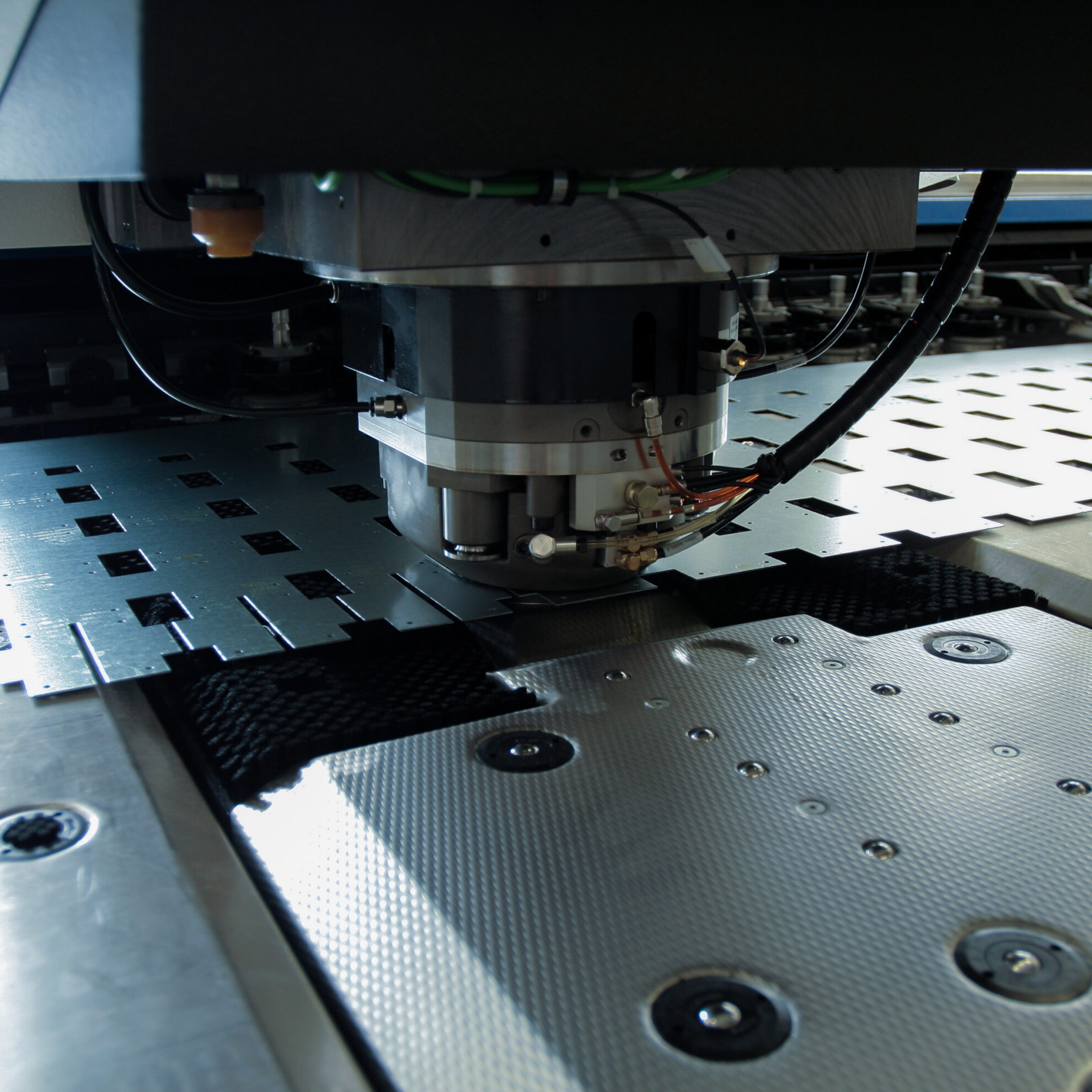

Vertikaalne masintöötlus- ja treikeskus Unisign UNICOM 7000

Jõuline treimine 5-teljelise masintöötlusega. Kõrge tootlikkus pikemate komponentide korral.

Kõrgem tootlikkus. Suurem maht ja rohkem ruumi tööalal… Unicom 7000 on võtmeks kõrgema tootlikkuse juurde suuremate komponentide korral. Sarnaselt oma vennale, Unicom 6000-le, pakub see masintöötluskeskus suurepärast tootlikkust kvaliteeti ohvriks toomata. 7000 erineb 6000-st selle poolest, et standardne konfiguratsioon hõlmab vertikaalset karusselljaama ning kaubaalusevahetit ja võimaldab märksa suuremaid kaubaaluseid. Vähem seadistusi, lühemad täitmisajad – see ülimalt täpne masin on parimaks valikuks suurte toorikute töötlemisel kõrget tootlikkust eeldava tootmistegevuse käigus.

Lühikesed täitmisajad

Tänapäeval ootavad kliendid sageli isegi suurte komponentide valmimist üha lühema ajaga. Unicom 7000 on meie kõige kohandatavam ja funktsionaalsem komplekstöötlusmasin. Lisaks suurte terasehulkade väga kiirele eemaldamisele võimaldavad selle kaubaaluse laadejaamad seadistamise sooritamist masintöötlustsükli käigus, mis tootlikkust veelgi tõstab. Niisuguse kombineeritud talitlusega kaasnevad lühikesed täitmisajad, mille juures ei tehta järeleandmisi treimis- ja freesimisvõimekuse osas.

Usaldusväärne töötlus

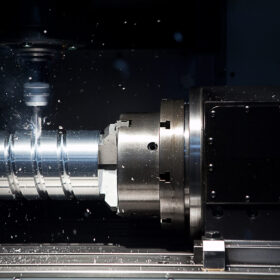

Unicom 7000 kaheastmeline käigukastiga ajam freesimiseks ja treimiseks võimaldab suurt väändemomenti ning pöörlemiskiirust. Masina liugur koos treitera adapteriga lubab „sukelduda“ tooriku sisse ja kasutada lühikesi, stabiilseid tööriistu. Protsessiaegset

mõõtmist võimaldav mõõtepea tagab tihedate istude usaldusväärse töötluse, hoides kokku aega.

Kordamistäpsus

Unicom 7000-l on mõõtepea protsessiaegseks mõõtmiseks, mis toimib tööriistavahetuse vajaduseta. Seoses sellega on seadistusjaama kordamistäpsus garanteeritav mõne mikroni ulatuses. Lõpptoodete veelgi suuremaid täpsusi lubab saavutada see, et masintöötluse seadistusi on algusest peale vähem. Mugavuse huvides on kogu masinas üksainus tööriistasüsteem treimis- ja freesimistööde jaoks. Ohutuse tagab täielikult suletud kabiin.

Kaubaalusevaheti

Täisnurkne jagamispea

Universaaljagamispea

5-teljeline konfiguratsioon

Mõõtmised protsessi käigus

| Tööpiirkond | |

| X-telg | 2.675 mm |

| Y-telg | 2.300 mm |

| Z-telg | 1.600 mm |

| Vertikaalne gabariit | 1.800 – 2.200 mm |

| Laud | |

| Laua suurus | 1.250 – 1.800 ø mm |

| Pöörderõngas | 2.000 / 2.200 ø mm |

| Spindel | |

| Käigukastiga käitatav spindel, parameetrid | 42 kW |

| 6.000 min-1 | |

| 1.600 Nm | |

| Karussell-treimisjaam | 70 / 95 kW |

| 25.000 / 38.000 Nm | |

| Erinevad tööriistad | |

| Koonus | HSK100A / Capto C8 |

| Pesade arv | # 97-200 |

| Tööriista vahetusaeg | 10 sek |

| Töökiirus | |

| Kiiretteanne | 40.000 mm/min |

| Etteandekiirus | 5-40.000 mm/min |