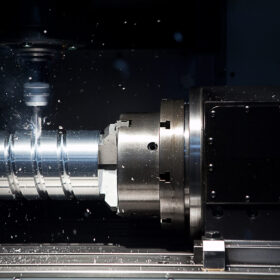

CNC treipink KOVOSVIT SP 430

Masin on vastupidav, raam on jäik.

Dünaamika ja suur kiirus üksikutel telgedel ning lühikesed sekundaarsed ajad tagavad seadme optimaalsema kasutamise.

Juhtimissüsteem SIEMENS, FANUC, HEIDENHAIN.

Y-teljel kõrge käik.

Spindli suur pöördemoment – efektiivne treimine ka maksimaalse läbimõõdu korral.

Rulljuhiku kasutamine kõigil telgedel tagab pikaajalise ülitäpse töötlemisvõimekuse.

Treipink on varustatud juhtimissüsteemi integreeritud ohutussüsteemiga – SAFETY INTEGRATED Siemensilt, DUAL CHECK SAFETY Fanucilt ohutusmoodulitega HEIDENHAINilt.

Seest tühi kinnitussilinder (vasak esipukk)

Seest täis kinnitussilinder (parem esipukk)

Vasaku ja parema spindli lukustus (mootorspindel)

Otsemõõtmine X1- ja X2-telgedel

Lineaartelgede absoluutmõõtmine

Tööriistajahutus – 17 baari

Tagapukk koos ühendusega

Masina valgustus

USB, Ethernet (vastavalt kontrollsüsteemi tüübile)

Tööriistakomplekt

Tehniline dokumentatsioon

Padrunid A8, A11

Erikinnitusrakised

Tööriistahoidikud

Kõrgsurvega tööriistajahutus – 17 baari, koos filtreerimisega

Vasaku spindli lukustus (rihmajam)

Kinnitusrakise läbipuhumine – parem esipukk

Detailide ejektor paremas esipukis

Osade püüdur

Latijuhik

Kohandus latisööturi jaoks

Latisöötur

Käsiloputus

Auruärastus tööruumist